Home » Shop » Daily Deals » Waterproof Solder Wire Connector Kit

Waterproof Solder Wire Connector Kit

$15.30 – $50.15Price range: $15.30 through $50.15

Your Purchase is Safeguarded by the WWW.COUGEX.NET Money-Back Guarantee

I’ve Done Hundreds of Crimp Connections. They Still Kept Failing. Turns Out the Problem Was Never My Technique.

How one simple switch gave me factory-quality splices that actually hold without a soldering iron or fancy tools.

.el-183345 .el-69520 { display:none;margin:10px 0px 10px 0px; }.el-183345 .el-69520 { align-items:center; }@media only screen and (min-width: 600px) and (max-width: 1024px) { .el-183345 .el-69520 { display:none; } }@media only screen and (min-width: 0px) and (max-width: 600px) { .el-183345 .el-69520 { display:inherit; } } .el-183345 .el-69520 img { box-shadow:none;object-fit:cover; } .el-183345 .el-69520 img { width:100%;height:auto; }

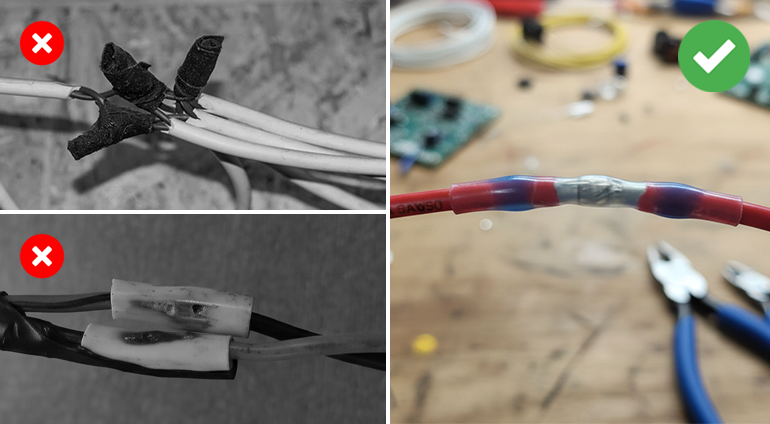

If you’ve been told “crimps are fine if you do them right”… and you’ve done them right and they still fail.

This is going to change how you think about every connection you’ve ever made.

Because the problem isn’t your crimper. It isn’t cheap connectors. It isn’t rushing the job.

What I’m about to share is the same reason military aircraft don’t allow crimps on critical systems. It’s why aerospace wiring holds for decades while trailer harnesses fail in months.

And it’s why I haven’t re-done a single connection in over 18 months.

No soldering iron. No fancy tools. Just a different approach that finally makes “done” actually mean done.

Take five minutes and read this. If you’ve ever felt that low-grade anxiety wondering whether your connections will survive the next trip – this is for you.

I’ve been wiring my own vehicles since I was a teenager. Cars, trucks, boats, trailers. I took pride in clean work: solid strips, tight crimps, shrink where it mattered.

So when connections started failing, I blamed myself. Thought I rushed. Used cheap connectors. I’d cut it out, redo it, and move on.

Then it kept happening.

The moment that broke me was a Saturday at the lake.

My son and I had planned this fishing trip for weeks. Two-hour drive. Boat in tow.

I backed the trailer down the ramp… hit the brakes… and watched the lights flicker once… twice… then die.

Now I’m knee-deep in the water, trucks lined up behind me, wiggling wires like an idiot while my kid pretends not to notice.

The whole day I kept thinking: “I did this right. Why can’t I trust my own work?”

Driving home with hazards on, I decided: No more band-aids. I’m figuring out why this keeps happening.

Here’s what I learned – once you hear it, you can’t un-hear it:

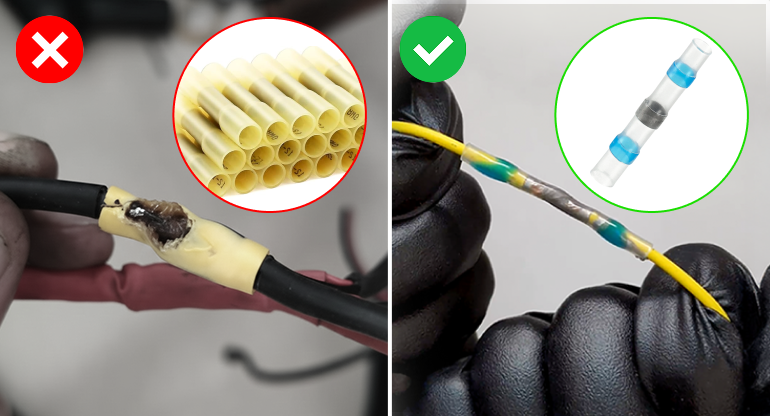

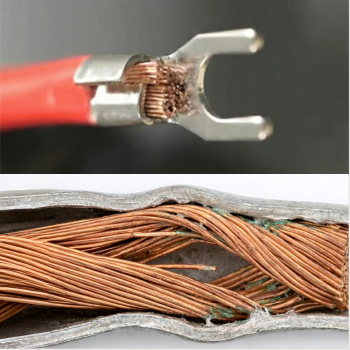

A crimp doesn’t bond the wire. It squeezes it.

Two pieces of metal, held together by pressure alone.

Picture holding two wires between your thumb and finger, gripping hard. How long could you hold it? A minute? An hour?

Now imagine 10 years. Highway vibration. Freezing winters. Blazing summers. Water creeping into gaps your grip couldn’t seal. That’s what we’re asking a crimp to do.

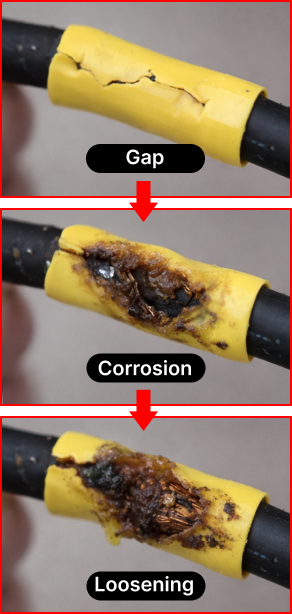

Those micro-gaps create resistance. Resistance creates heat. Heat speeds corrosion. Corrosion widens the gaps.

A slow failure built into the design.

It was never about technique. Never about a better crimper. The method itself is flawed.

That’s when I stopped searching for a better crimp and started searching for a different method entirely.

Years ago, a buddy who worked on aircraft told me something I never forgot:

“They don’t use crimps on anything critical.” I asked what they use instead.

“Soldered connections. Fused. Permanent. The wire becomes one piece.”

I’d always brushed off soldering for auto work. Too slow. Too messy. Hard to do under a trailer in a gravel lot.

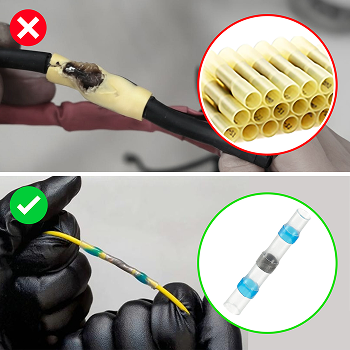

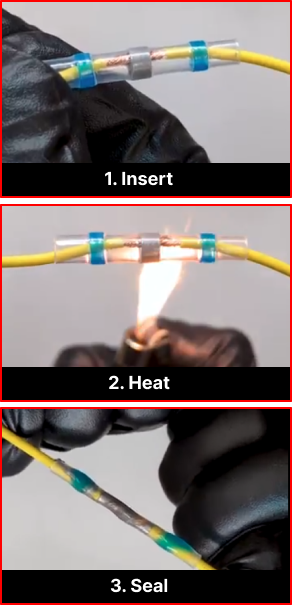

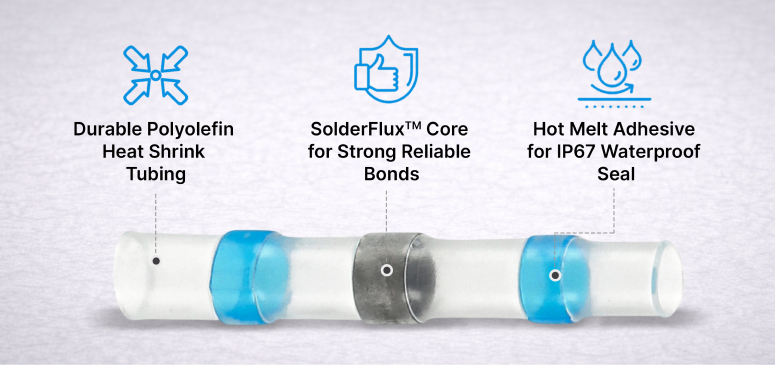

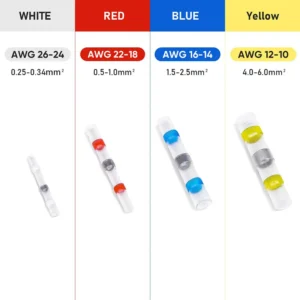

But digging deeper, I discovered something I didn’t know existed: a connector that gives you solder strength without a soldering iron.

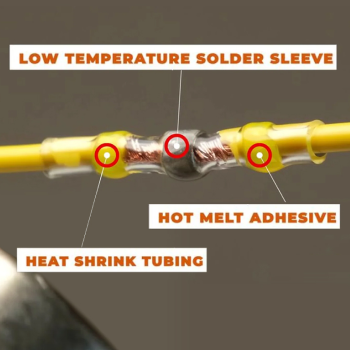

Inside is a ring of solder. Apply heat, the solder melts and flows through the strands. The outer sleeve shrinks and seals with adhesive.

Instead of a squeeze – you get a bond.

Think of it like clamping two pieces of metal together versus welding them into one.

A clamp can loosen. A weld is permanent.

No gaps. No wiggle. No slow corrosion spiral.

If this technology works so well, why isn’t it everywhere?

Because aerospace and military have used it for decades but never sold it to consumers. Bulk-ordered by manufacturers, engineered to mil-spec standards, locked behind industrial supply chains.

We got crimps. Because that’s what the parts store carried.

Until recently.

Making this work requires precision. The solder alloy needs the right melting point. The tubing must shrink after the solder flows. The adhesive must bond to copper, resist moisture, and stay flexible through years of temperature swings.

Get any of it wrong, the connection fails.

But someone finally figured out how to bring it to consumers. Done right.

That’s when I found KLENIMORE™ solder stick.

A friend in a marine electrical forum mentioned them. Said they were the first company he’d seen actually bring aerospace-grade solder-seal technology to regular DIYers.

I was skeptical. But I ordered a kit anyway.

The difference was obvious the moment I used them.

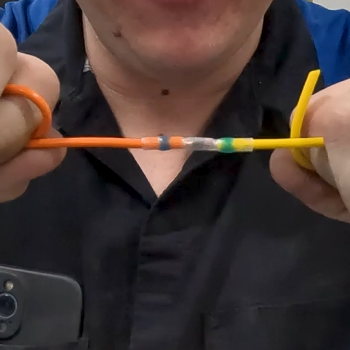

I stripped my wires, slid them in, applied heat. Within seconds, I watched the solder melt and actually flow into the wire strands. The tubing shrank tight. The adhesive squeezed out at the edges, sealing everything.

No guesswork. No hoping it worked. I could see it happening.

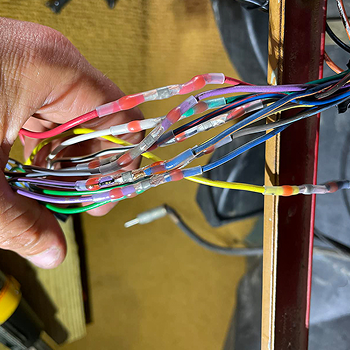

I used them on a trailer harness I’d already re-crimped twice that year.

That was 18 months ago.

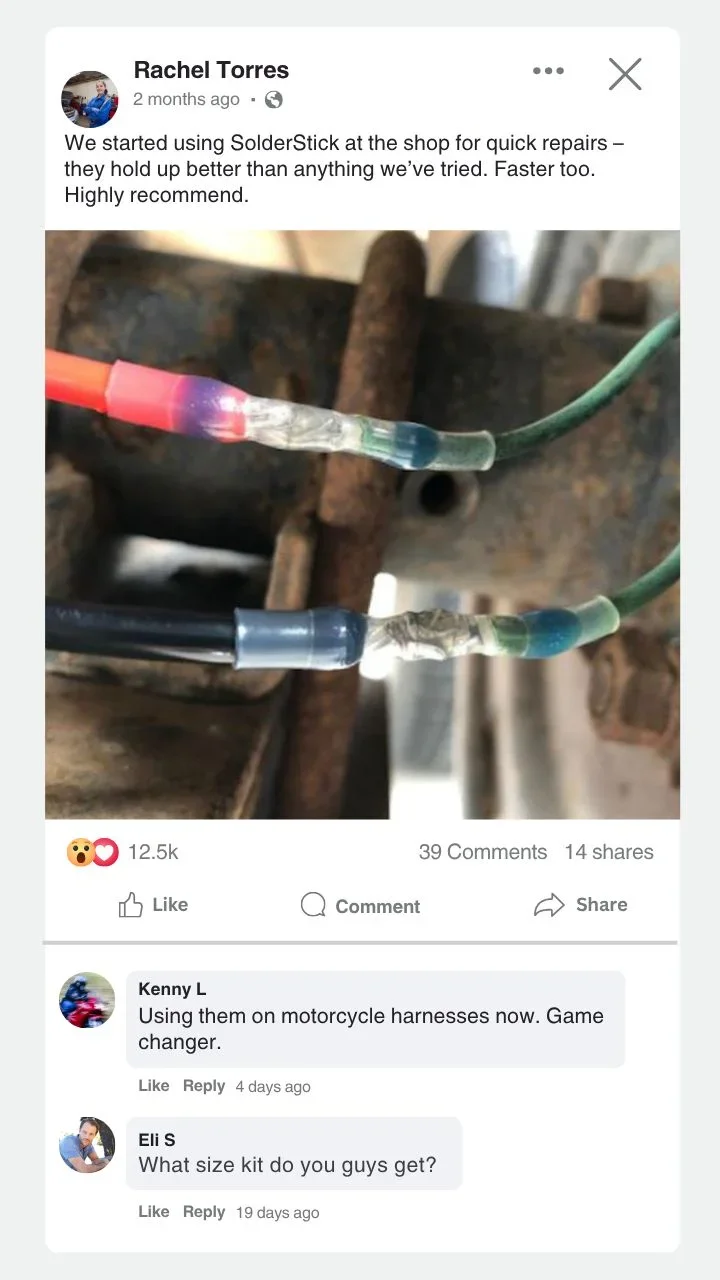

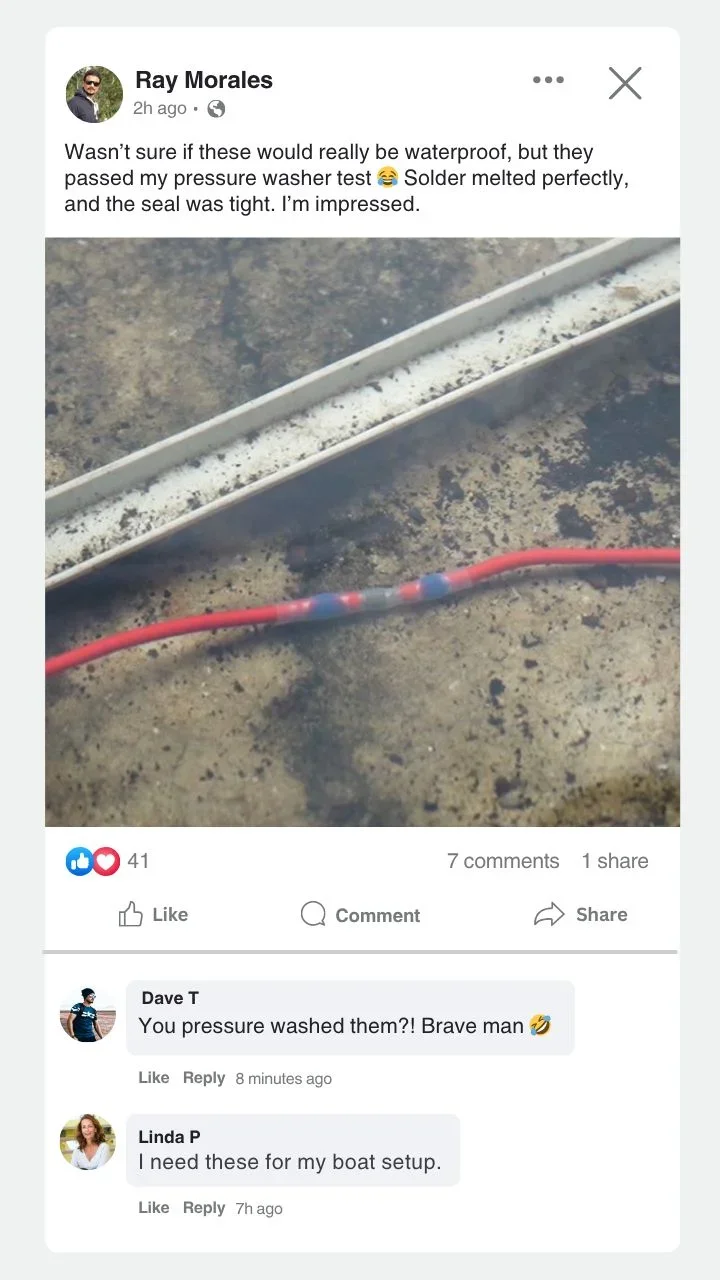

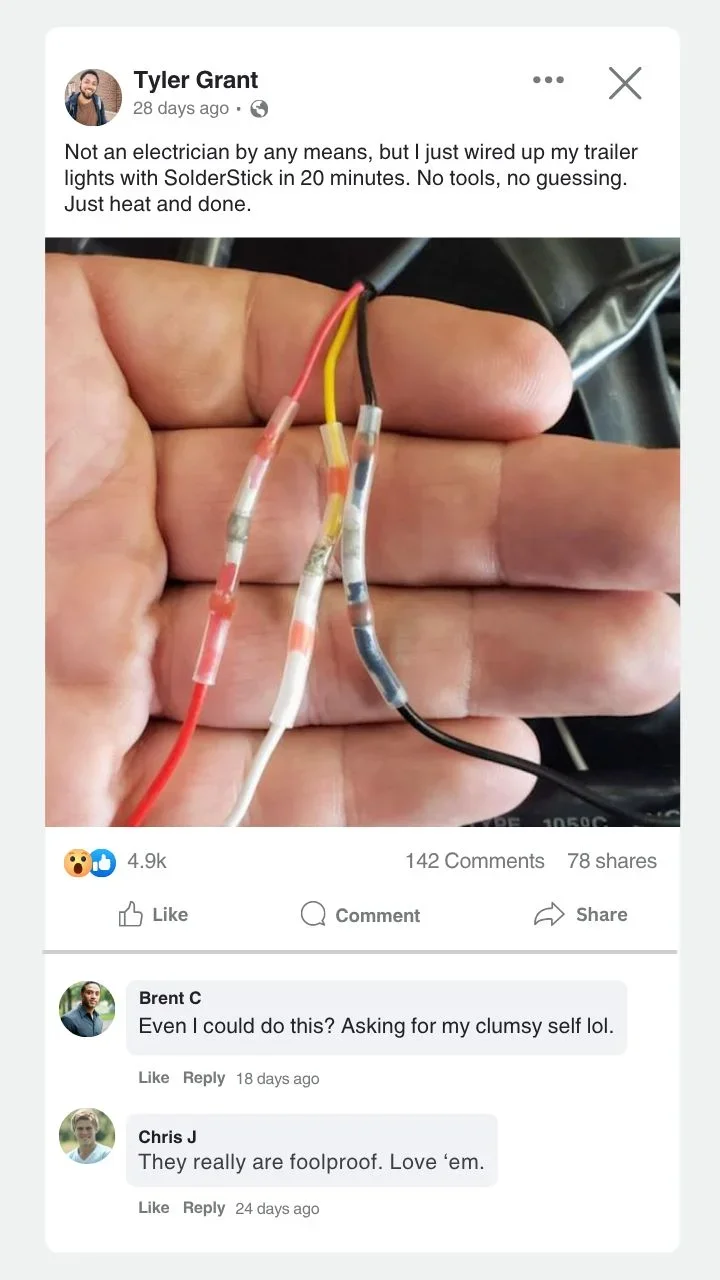

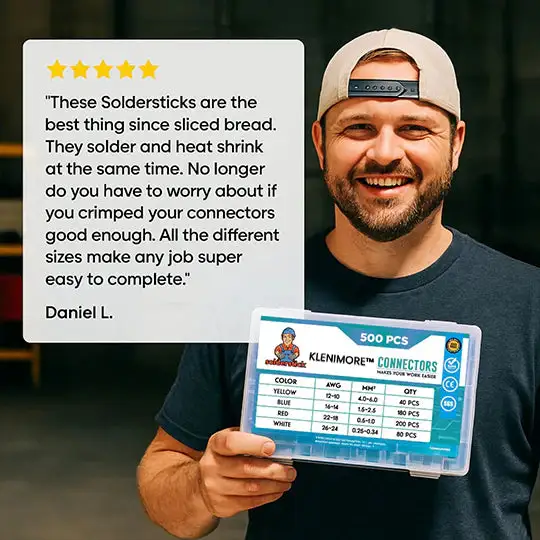

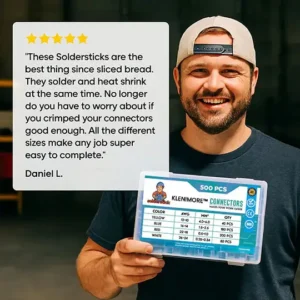

Don’t Take My Word For It

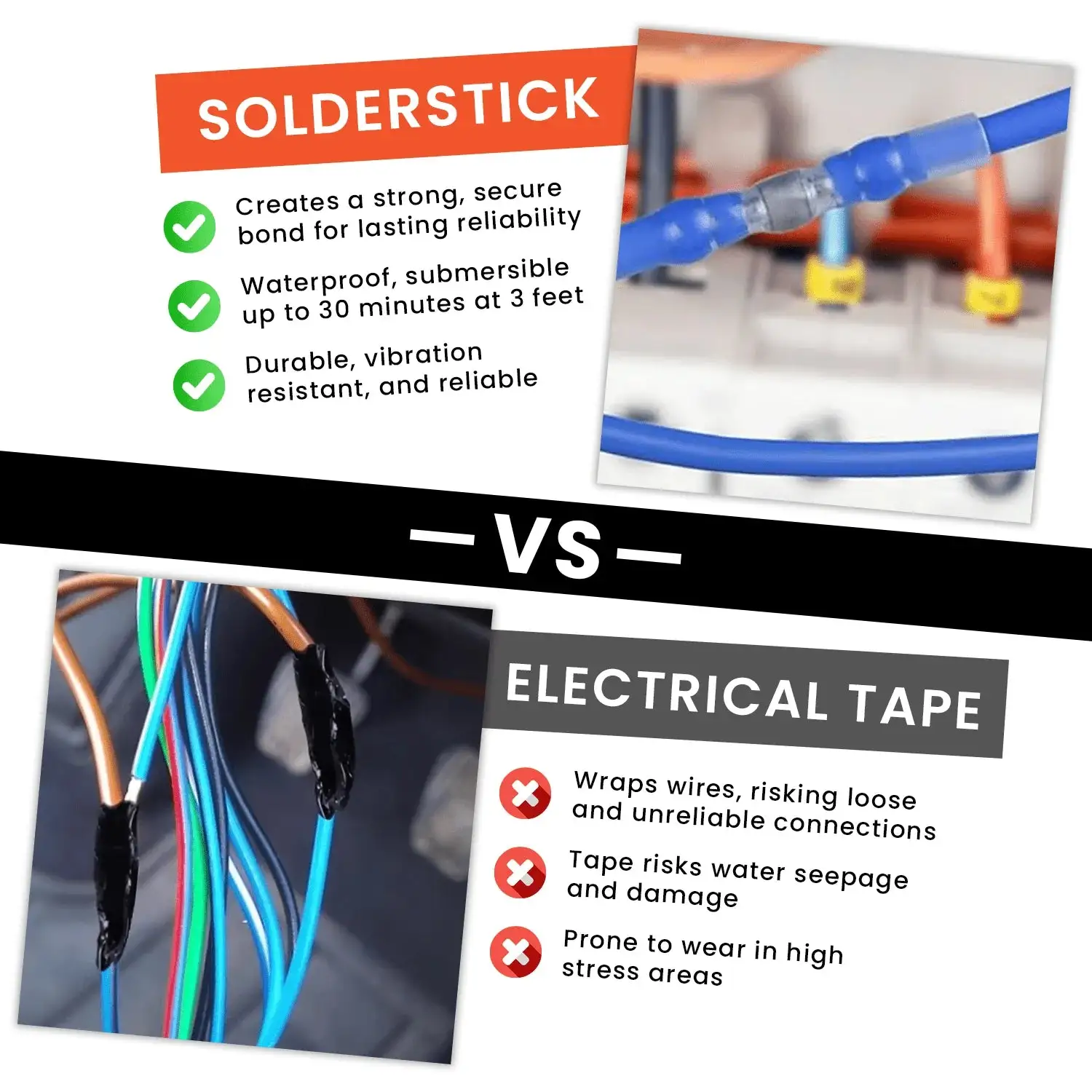

YouTube mechanics have put these through torture tests – submerging them in water, yanking on them with fish scales.

The results?

❌Tape connections: Failed at just 5 pounds of force.

❌Crimp connectors: Broke loose at around 10 pounds.

✔️SolderStick: Held strong at over 30 pounds – no weakening, no breaking.

The wire breaks before the connection fails.

That’s not marketing. That’s physics. A molecular bond versus a mechanical squeeze.

What Guys Are Saying After Making the Switch:

Now, Let’s Talk About What This Costs

I’m not going to pretend KLENIMORE™ solder stick is the cheapest option. It’s not.

But here’s what you’re paying for:

This isn’t something thrown together to hit a price point.

✔️The right solder alloy with the right melting point

✔️Dual-wall tubing that shrinks after the solder flows

✔️Adhesive lining that actually seals

✔️Quality control that catches problems before they reach you

That’s aerospace-grade engineering, made accessible.

That’s why this method is trusted for systems where failure means someonedoesn’t come home.

And that’s why I stopped wasting money on connections that didn’t hold.

Here’s How I Think About It

A professional marine electrician charges $85-150/hour. One trailer rewire?

You’re looking at $300-500 in labor alone.

A single roadside assistance call when your trailer lights die two hours from home? $150 minimum. Plus the hassle. Plus the ruined trip. Plus explaining to

your wife why you’re sitting on the shoulder again.

And how much have you already spent on crimp connectors, heat shrink,electrical tape, and your time redoing the same connections over and over?

A KLENIMORE™ solder stick kit costs a fraction of one service call. And it’ll handle dozens of connections – each one permanent, each one reliable, each one you’ll never have to touch again.

One Thing to Keep in Mind

KLENIMORE™ solder stick isn’t always in stock. These aren’t mass-produced in some overseas factory churning out millions of units. They’re made in smaller batches with actual quality control.

When a batch sells out, it takes time to restock.

I’m not saying that to pressure you. I’m saying it because I’ve been the guy who found something that works, waited too long, and then couldn’t get it when I needed it.

If this makes sense to you – if you’re tired of crimps failing and you’re ready to try something that actually holds – don’t put it off and forget about it.

Right now, you’re at a crossroads.

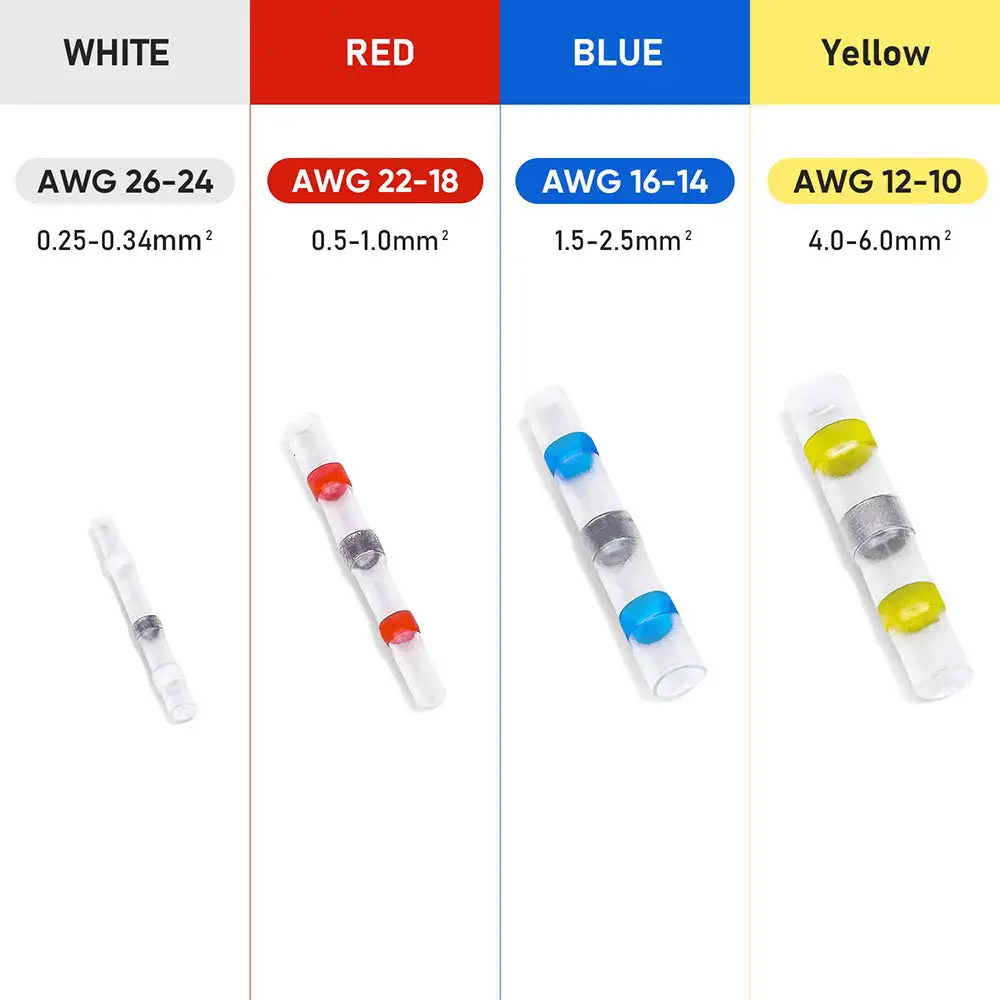

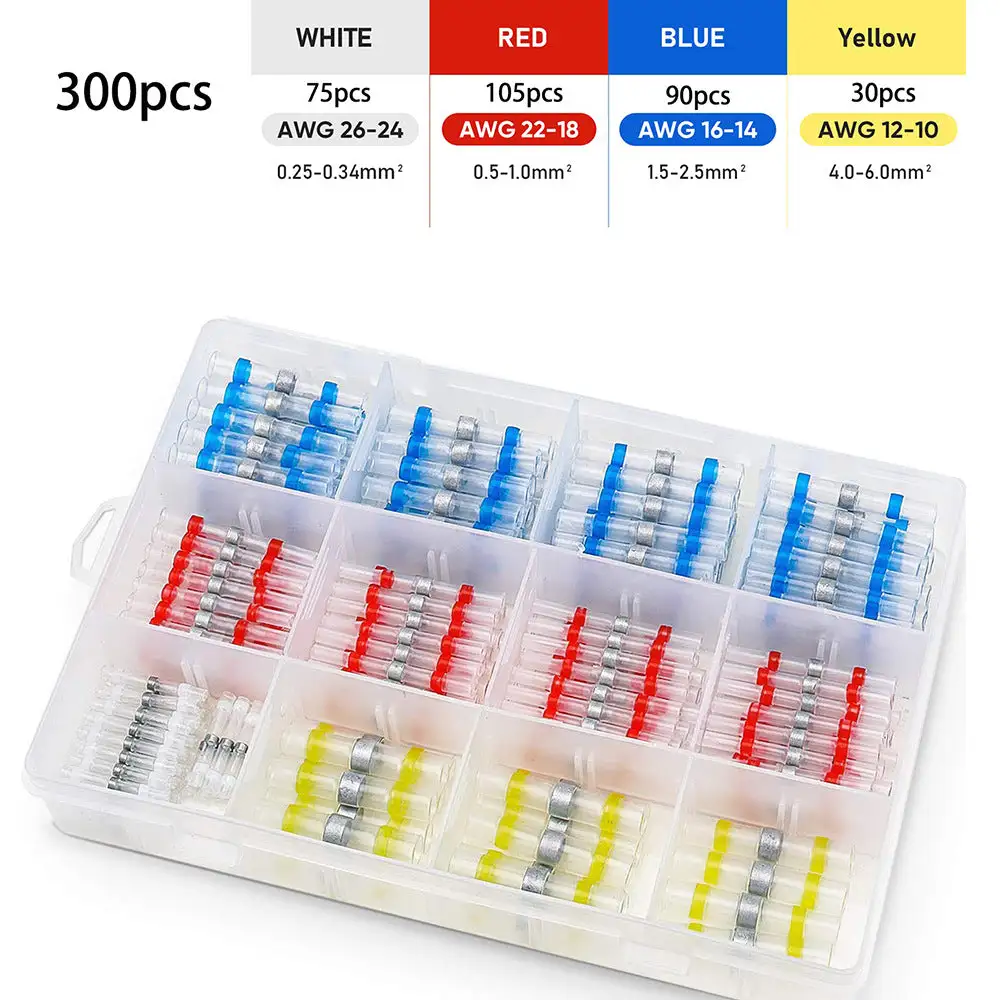

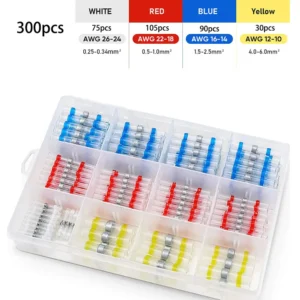

| Package | 1PC, 3PCS, 5PCS |

|---|

Be the first to review “Waterproof Solder Wire Connector Kit” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.